Development of inline cleaning for washing media in resin-based 3D printing production

Project Inline3D launched to minimize pollutants and costs in 3D printing

On September 11, 2025, IMMS, IL Metronic, and BURMS presented details of the Inline3D project, funded by Thuringia and the EU and launched in June, to the Thuringian Development Bank in Erfurt. This nearly two-and-a-half-year project will develop sensor, cleaning, and fluidic modules to enable the inline cleaning of washing media during resin-based 3D printing – directly within the manufacturing process – for the first time. The goal is to minimize the use of environmentally and health-damaging, as well as costly, substances in the washing media required for 3D printing.

Resin-based 3D printing processes produce harmful waste

In resin-based 3D printing, the 3D printed objects are cleaned with special washing agents. These contain environmentally and health-damaging substances and are currently often disposed of after a single use instead of being recycled. The reason is that, at present, recycled washing agents are usually insufficient to adequately remove uncured resin from the printed objects.

The cost factor of washing media has been difficult to minimize so far.

The consumption of cleaning media is also a significant cost component in the production process. Currently, cleaning media are only processed on a large industrial scale. Available cleaning equipment is large, unwieldy, energy-intensive, and can only be used offline. This means that the media to be cleaned must be transported to the cleaning system in separate process steps and later partially returned to the 3D printing process. Automated cleaning during the ongoing production process with continuous monitoring of the media properties is not yet available.

Inline processing allows reuse of the cleaning medium.

The Inline3D project is developing a cleaning media reprocessing process that removes impurities directly during production and then returns the reprocessed cleaning medium to the cleaning process. This treatment The environmentally and health-hazardous components are converted into harmless waste products that do not need to be disposed of as hazardous waste.

By monitoring the degree of contamination using sensors, the service life of the cleaning medium can be extended and the quality of the cleaning process optimized. The aim is to use resources more efficiently and to minimize pollutants and costs in 3D printing production processes.

Thuringian partners combine expertise in sensor technology, UV irradiation technology and 3D printing.

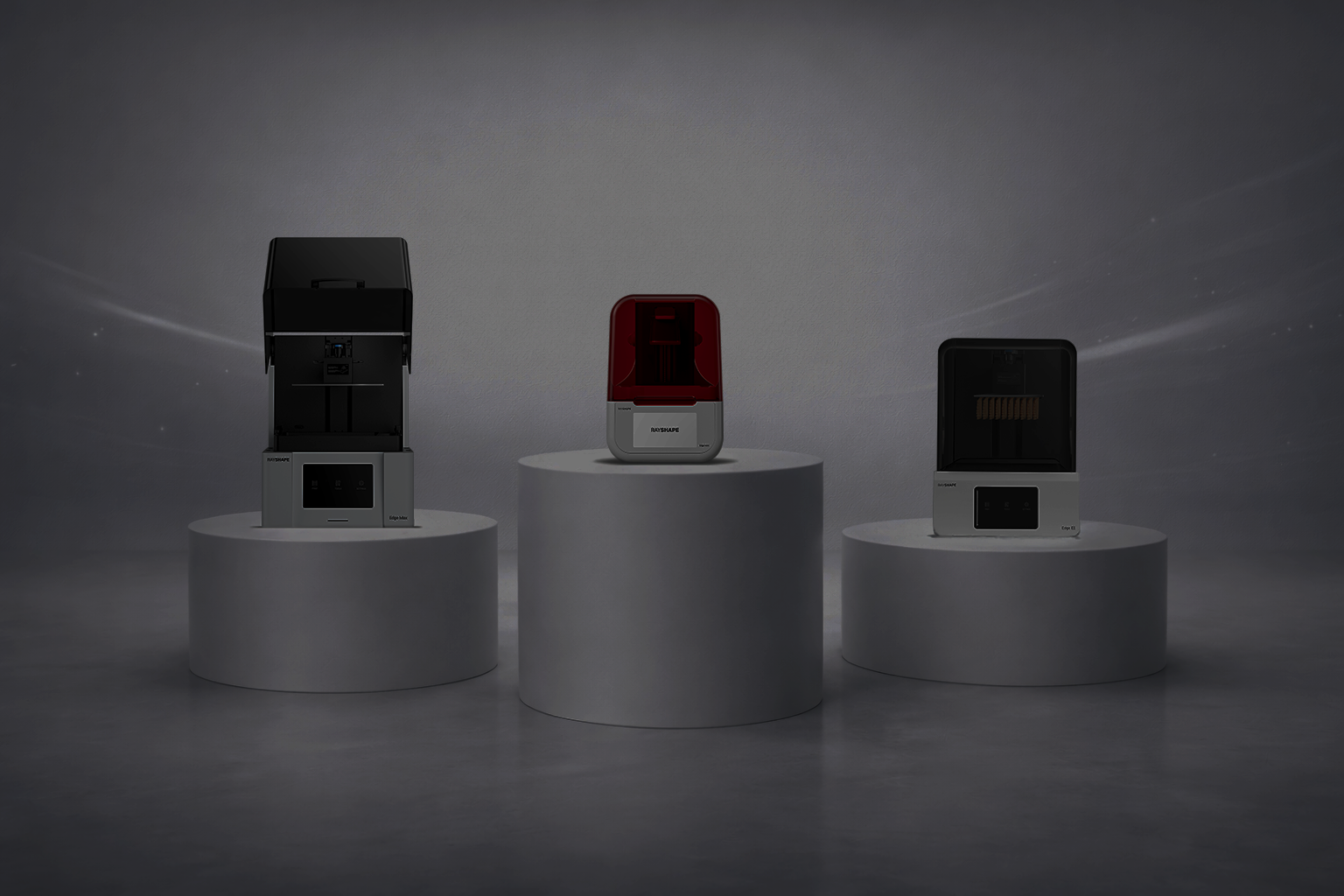

The regional network of the three Thuringian project partners BURMS 3D Druck, IL Metronic Sensortechnik and IMMS Institut für Mikroelektronik- und Mechatronik-Systeme promotes the innovation and further development of existing competencies in the field of 3D printing in Thuringia.

IMMS is coordinating the project and developing a sensor-based measurement method to quantify the degree of contamination in the washing medium. IL Metronic is leveraging its expertise in UV irradiation technology to integrate the measurement method into a sensor module and to develop an irradiation module for precipitating the dissolved resin residues. BURMS is contributing its expertise through its commercial 3D printing solutions, implementing the fluidics and process integration within the project, and ensuring device safety, disposal, and biocompatibility.

Faster production and more resource-efficient small batches are possible.

Due to the advantages of fast production times and application- and customer-specific customization of individual pieces, growth is expected, particularly in medical applications. In addition to the technological advancement of partner BURMS' 3D printing technologies, the project aims to use these technological insights to further develop 3D printing systems that currently do not process the washing medium.

Financial support

The joint project “Inline cleaning process for washing media in resin-based 3D printing processes” (Inline3D) is funded by the funding program of the Free State of Thuringia for the promotion of research, technology and innovation (FTI) as a research and development project Thuringia consortium under project number 2024 VFE 0113 and is co-financed by the European Union.

Source: https://www.imms.de/aktuelles/pressemitteilungen/d/entwicklung-einer-inline-reinigung-fuer-waschmedien-in-harzbasierter-3d-druckproduktion-5378.html

BURMS – 3D Printing Jena GmbH & Co. KG

📍 Visit us in Kahla · Im Camisch 4 · 07768

💡 Learn more about our solutions: www.burms.de

📅 Book an online consultation now: make an appointment