Burms finish degrees

Post-processing for 3D printing

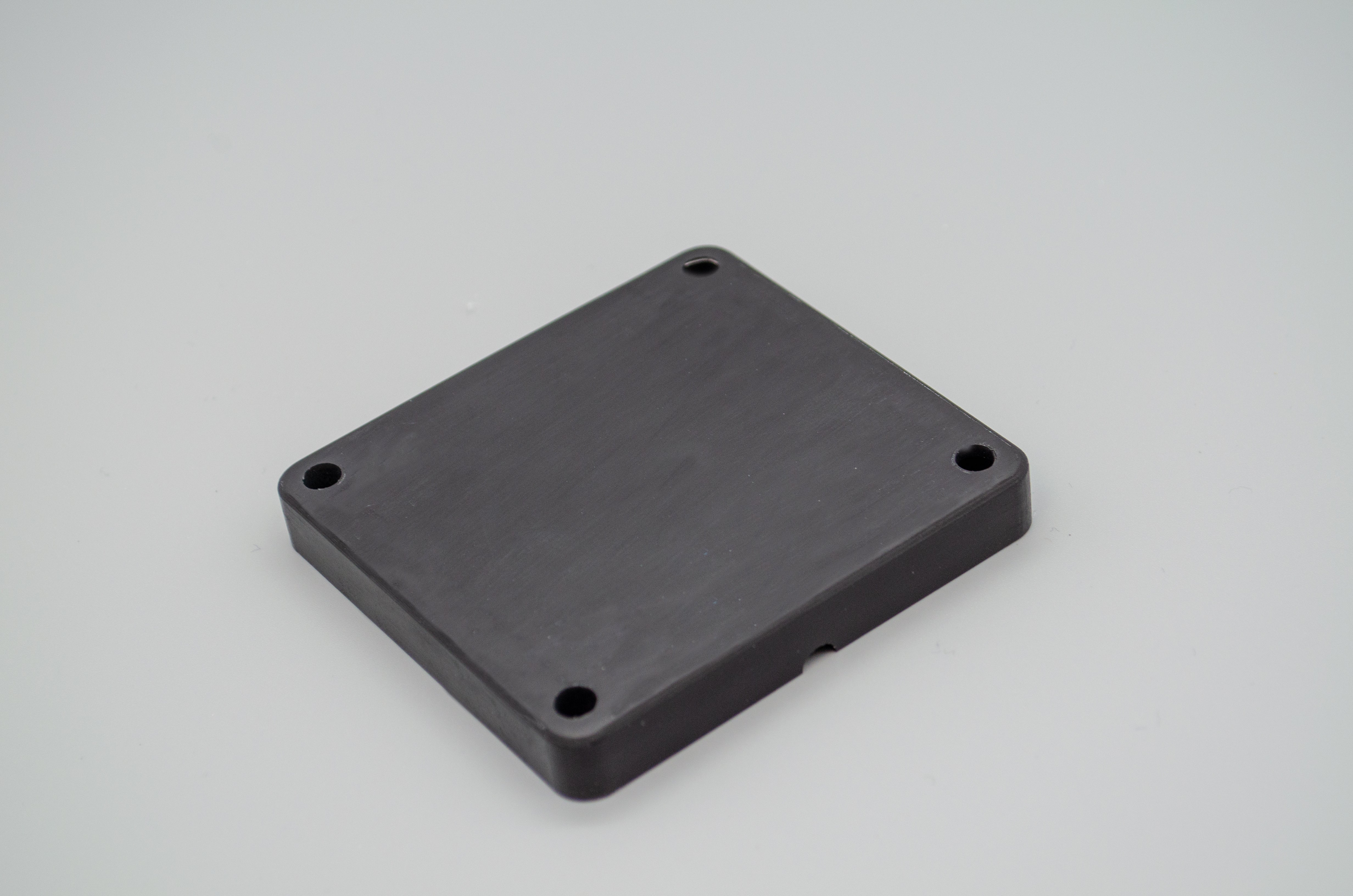

We produce your component and optimize both its mechanical and optical properties according to your requirements! Whether it's tear resistance, stability, or integrity, we ensure the component meets high standards. We help you find a suitable individual solution as well as an optimal series solution for the surface finishing of your component.

We wash, expose, temper, grind, polish, blast, dye, varnish, fill, insert threads and much more...

Contact us and we will help you find the right solution for your component.

Finish 1

The support structures of the component are removed and the

The component is post-exposed with UV light so that it hardens and acquires the desired material properties.

Finish 2

In addition to removing the support structures and the

After post-exposure, the component is sanded to remove any remaining surface imperfections and give the component a pleasant, smooth finish. Furthermore, the component is glass bead blasted to ensure a homogeneous surface.

Tools: Sandpaper (grain < 600), glass bead blasting machine

Finish 3

Component surfaces are sanded/polished or glass bead blasted for a superior surface finish. The components can be painted.

Tools: Sandpaper (grain < 1000), polishing machine, glass bead blasting machine, RAL color paints

Finish 4

In addition to glass bead blasting, the surface of the component is finished with a lacquer. Special services are included.

Tools: Sandpaper, RAL color paints, polishing machine, glass bead machine, thread inserts, component assembly, special packaging

support

Do you have questions or need support in choosing the right manufacturing process?

Then contact us - one of our employees will help you as soon as possible!