Information about the SLA print

Stereolithography

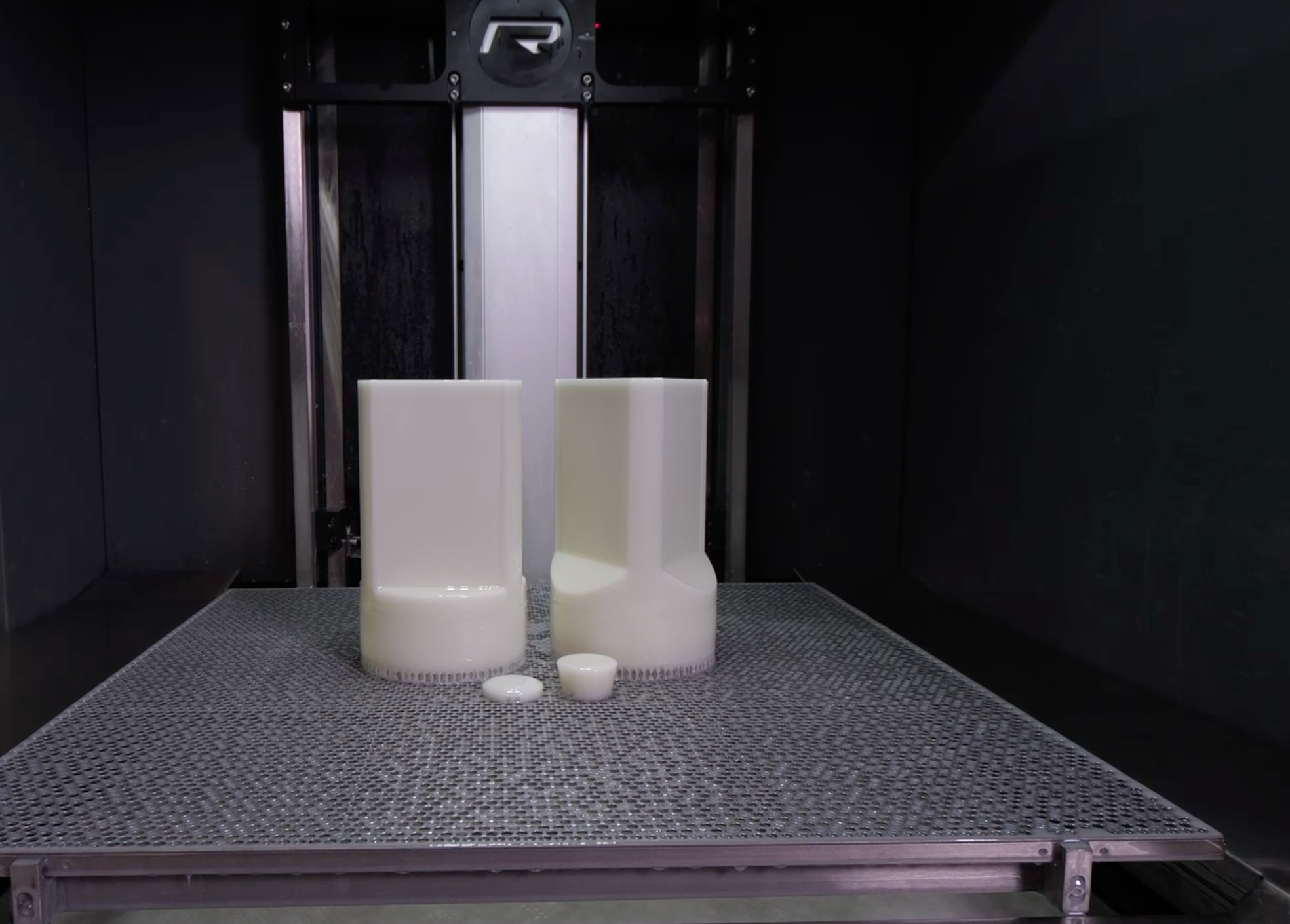

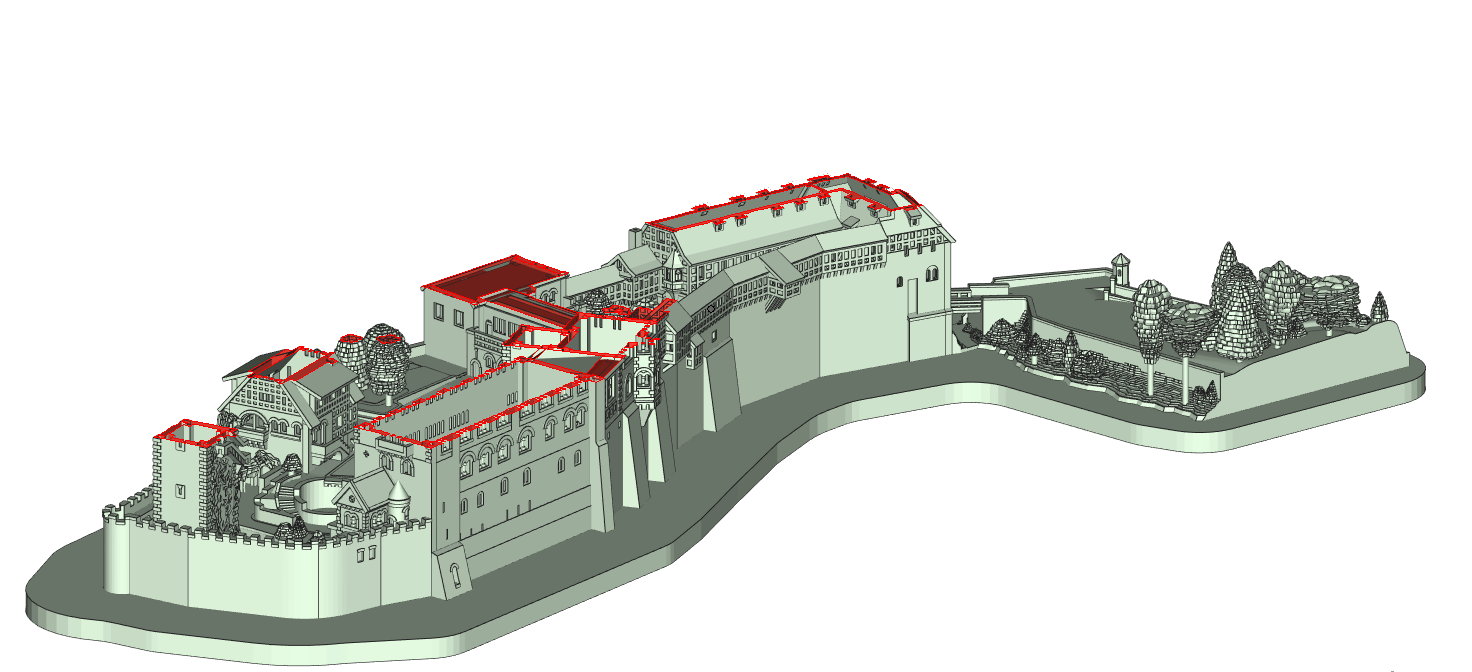

SLA printing is the first port of call for large functional parts, exhibits and small series production, particularly due to its large build volume.

We have an online calculator where you can upload and configure your 3D model. You'll then receive the price directly and can send us an inquiry.

For questions: order@burms.de

You are welcome to book an online appointment with us so that we can support you with any questions.

Book an appointment now!

3D printing technology

Procedure expiry

#1

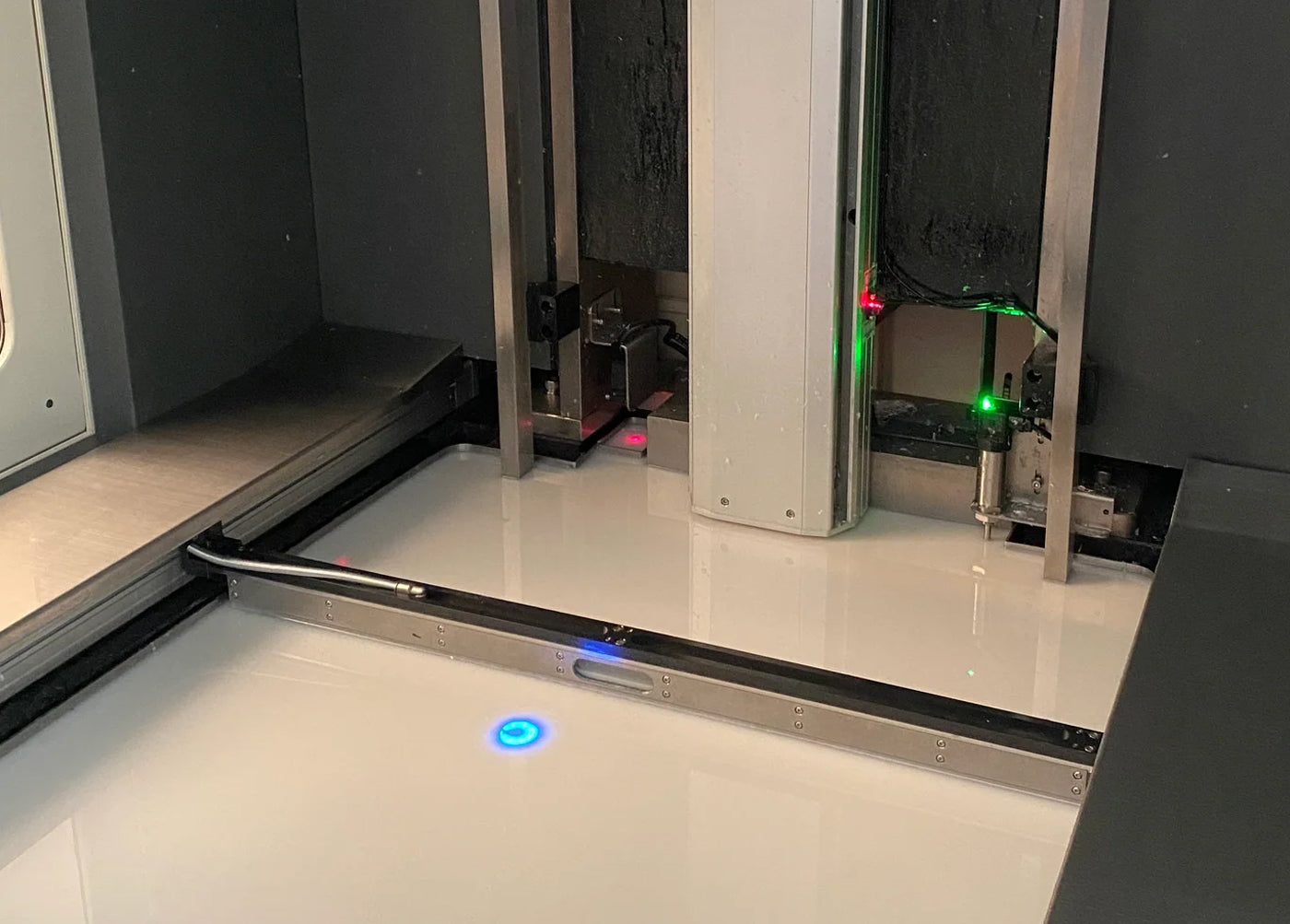

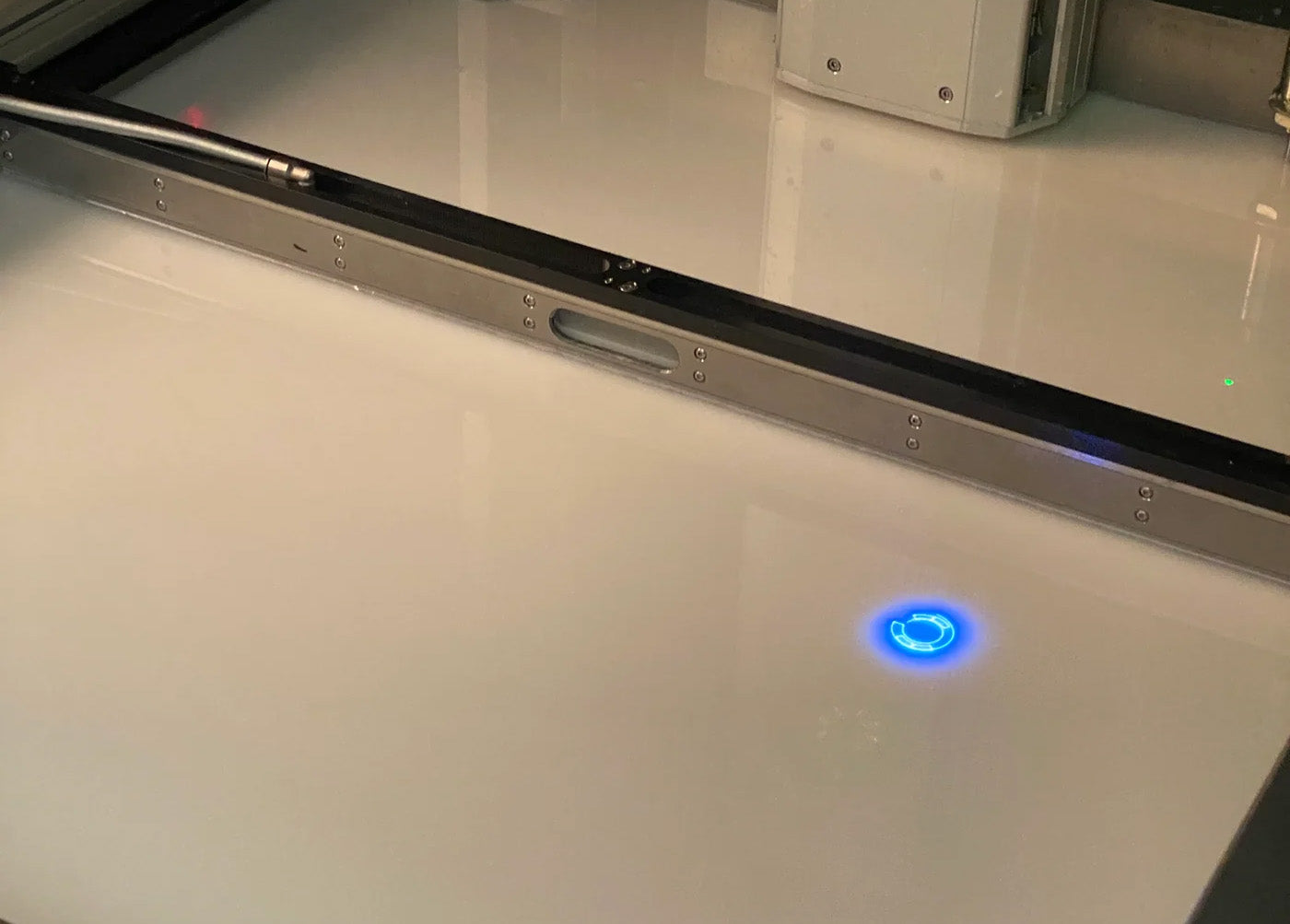

During printing, a build platform is lowered step by step into a resin tank. The distance traveled by the build platform corresponds to the layer height of the component to be manufactured.

#2

A UV laser is directed (using two mirror galvanometers) onto the build platform so that every point along the length and width of the build platform is reached.

#3

The directed UV laser cures a layer of the component to be produced along a predefined path. In an iterative process, all necessary layers of the component are created in the same way at impressive speed, resulting in a high-quality component.

Post -processing

From the idea to implementation + post-processing

previously

afterward

For post -processingsupport

Do you have questions or need support in choosing the right manufacturing process?

Then contact us - one of our employees will help you as soon as possible!