Information about the FDM print

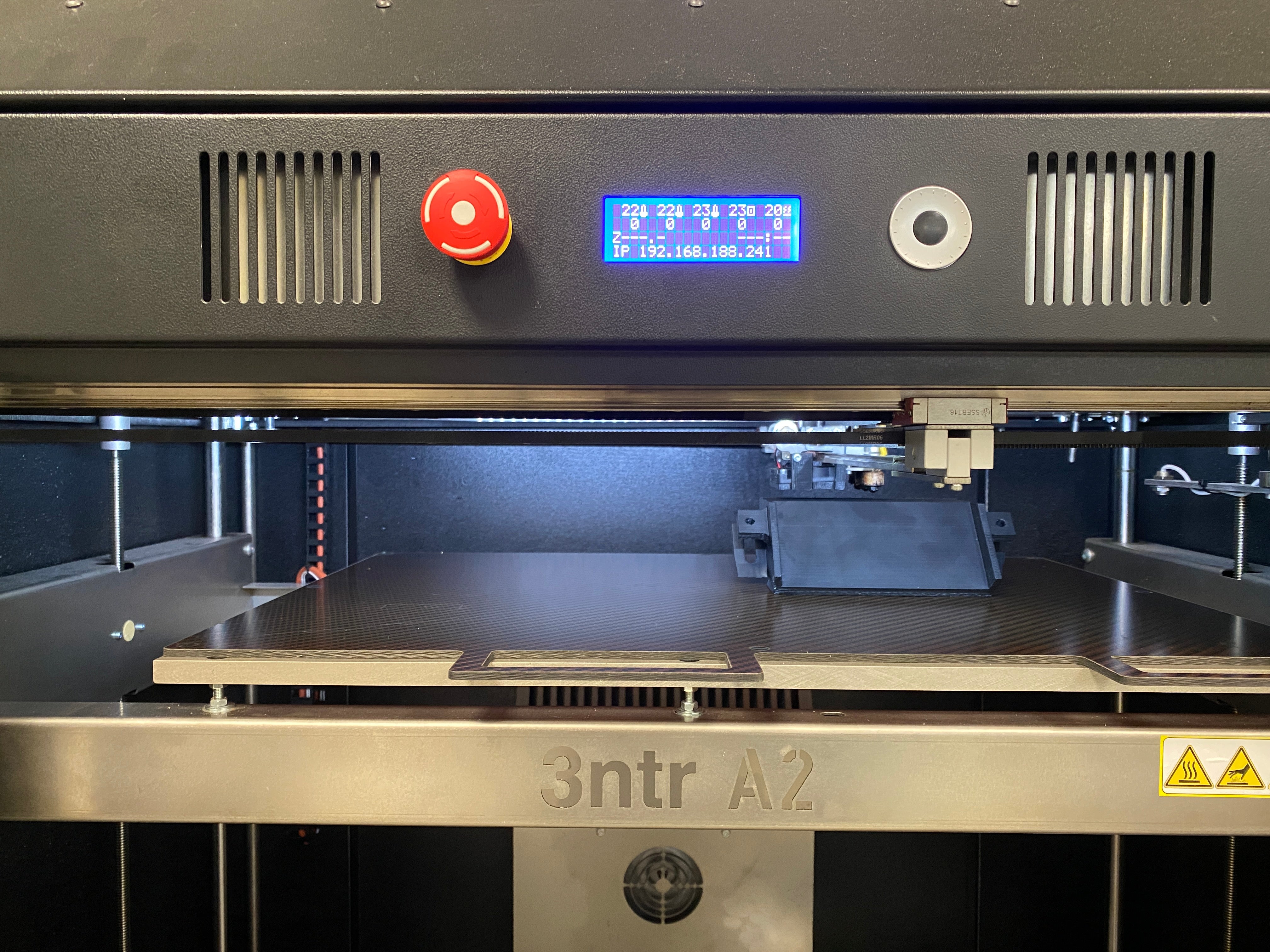

Fused deposition modeling

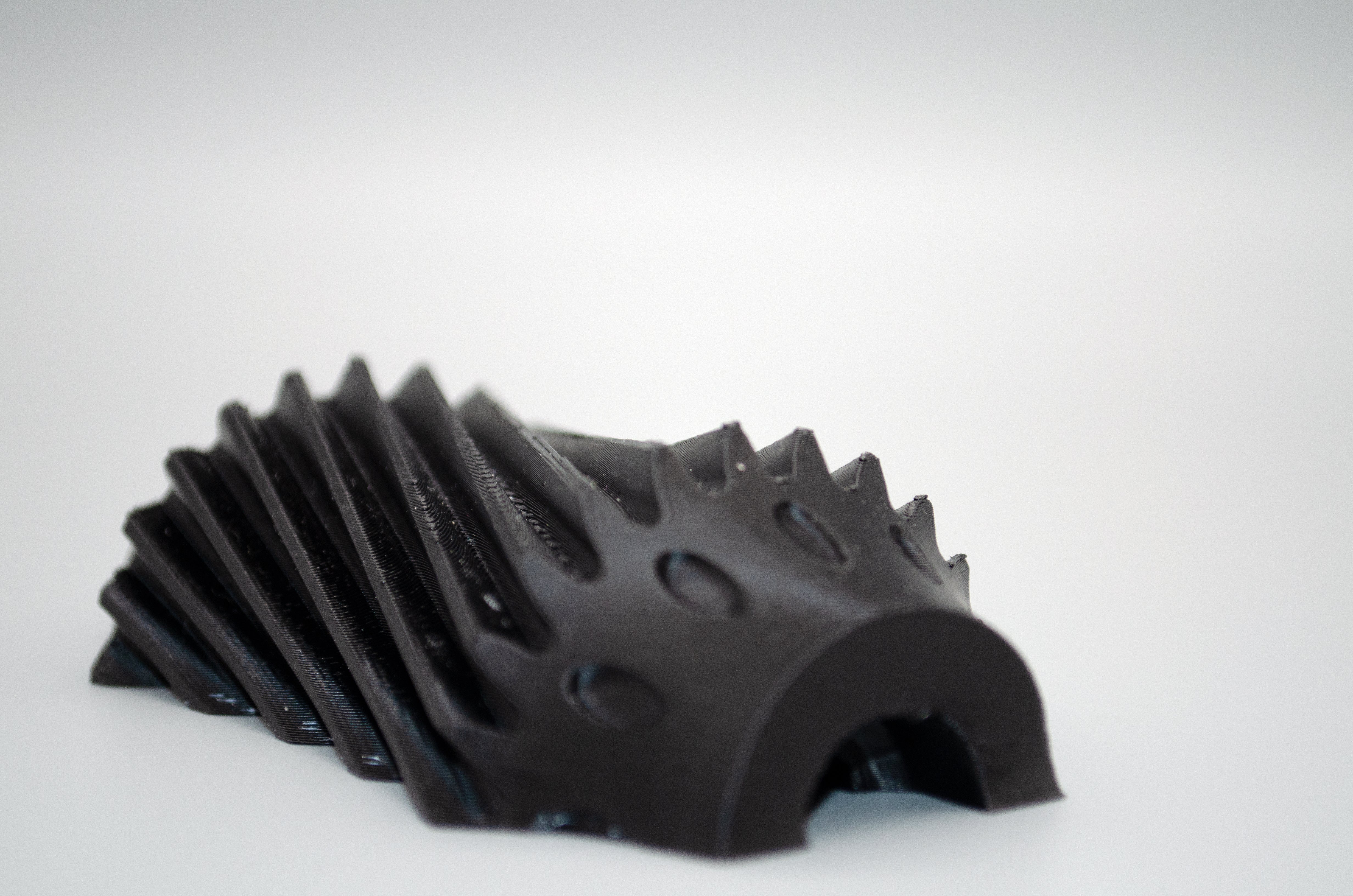

If components need to be produced quickly and cost-effectively, FDM printing is the first choice. Its large build volume makes FDM printing particularly popular for producing large prototypes.

We have an online calculator where you can upload and configure your 3D model. You'll then receive the price directly and can send us an inquiry.

For questions: order@burms.de

You are welcome to book an online appointment with us so that we can support you with any questions.

Book an appointment now!

ABS is a plastic primarily used in household and consumer products. Automotive and electronic components, motorcycle helmets, toys, housings for electrical appliances and computers, and consumer goods with increased impact resistance are typical products made from ABS.

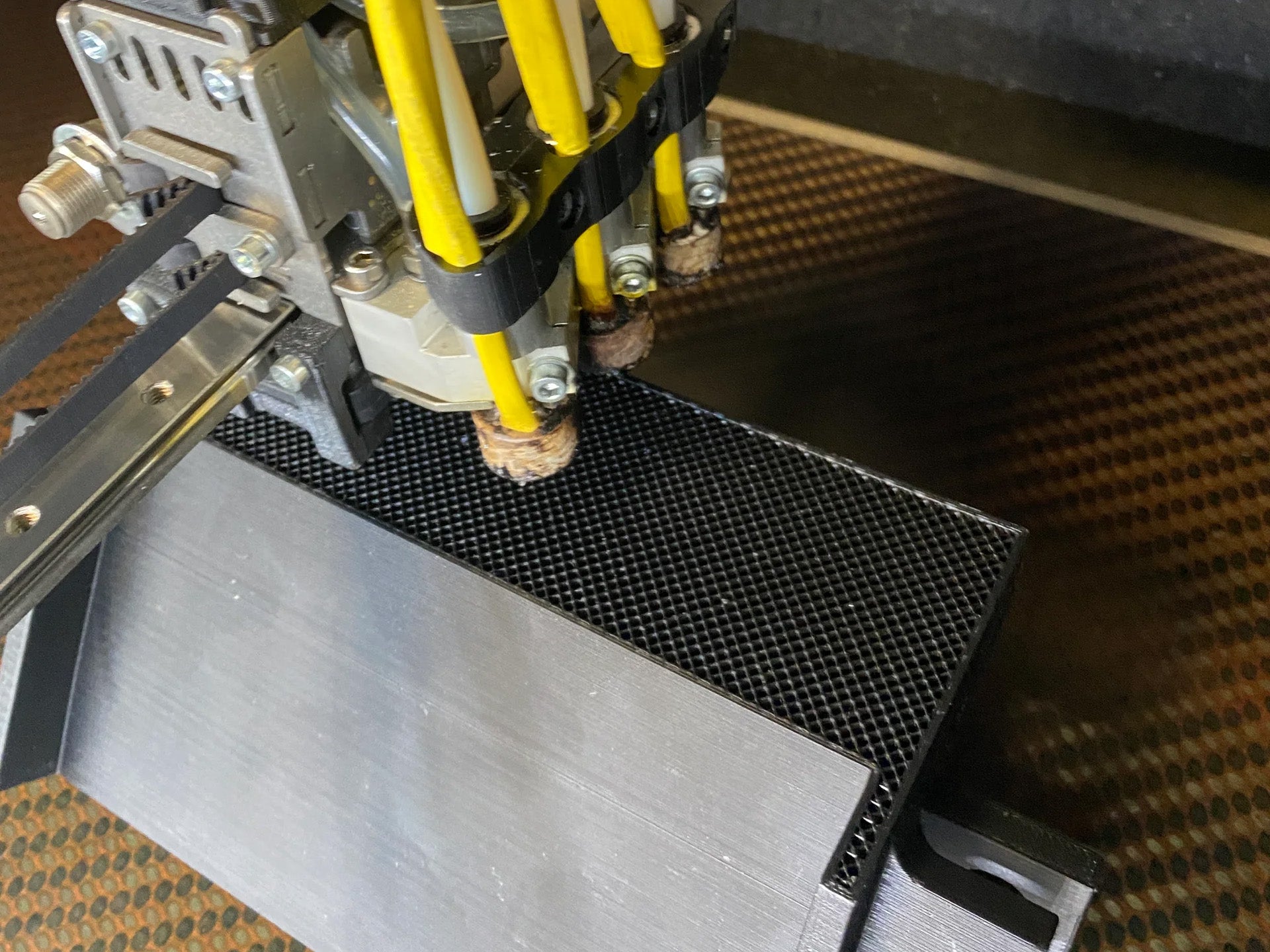

3D printing technology

Procedure expiry

#1

In FDM printing, a movable print head is moved along a predefined path in a fixed three-dimensional space. Along the path, the print head (extruder) melts a thin filament, usually ABS or a similar plastic.

#2

The molten filament is applied layer by layer to the heated build platform until all layers of the model are printed.

ABS - Material

specifications

45

30 - 45

1875 - 2300

6 - 10

36 - 75

ABS is a plastic primarily used in household and consumer products. Automotive and electronic components, motorcycle helmets, toys, housings for electrical appliances and computers, and consumer goods with increased impact resistance are typical products made from ABS.

support

Do you have questions or need support in choosing the right manufacturing process?

Then contact us - one of our employees will help you as soon as possible!