Information about the DLP print

DLP 3D PRINTING

DLP printing is particularly popular in dental labs and jewelry workshops due to its very high speed. DLP is also ideal for small functional parts and everyday objects.

We have an online calculator where you can upload and configure your 3D model. You'll then receive the price directly and can send us an inquiry.

For questions: order@burms.de

You are welcome to book an online appointment with us so that we can support you with any questions.

Book an appointment now!

Dental, Jewelry, Hearing Aids, Medical Devices, Functional Parts, Manufacturing, Research

3D printing technology

DLP printing process

#1

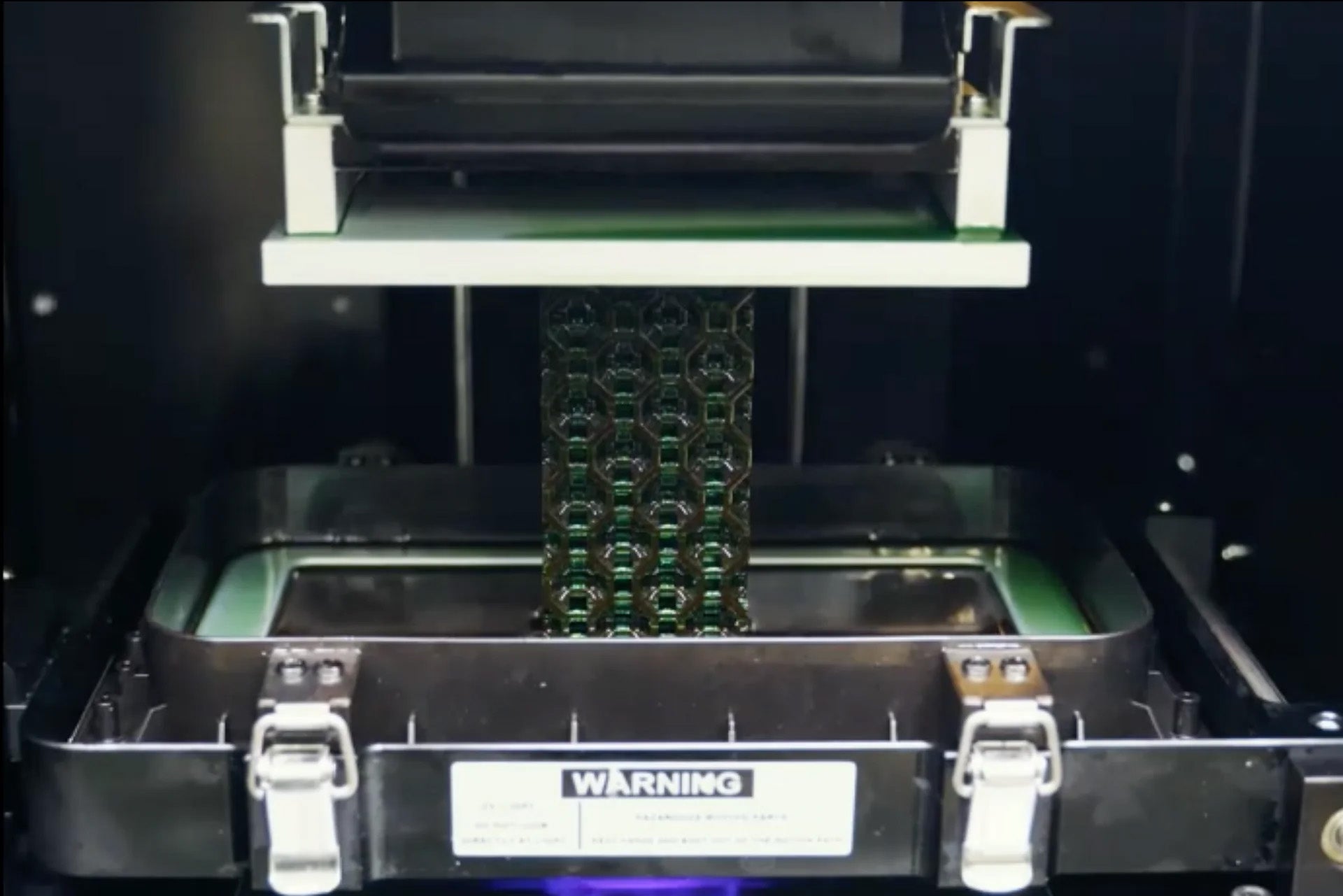

In DLP printing, a build platform is lowered into a resin-filled tank. The build platform moves into the tank until a gap of a defined height forms between the build platform and the tank bottom. This distance corresponds to the layer thickness with which the components are manufactured.

#2

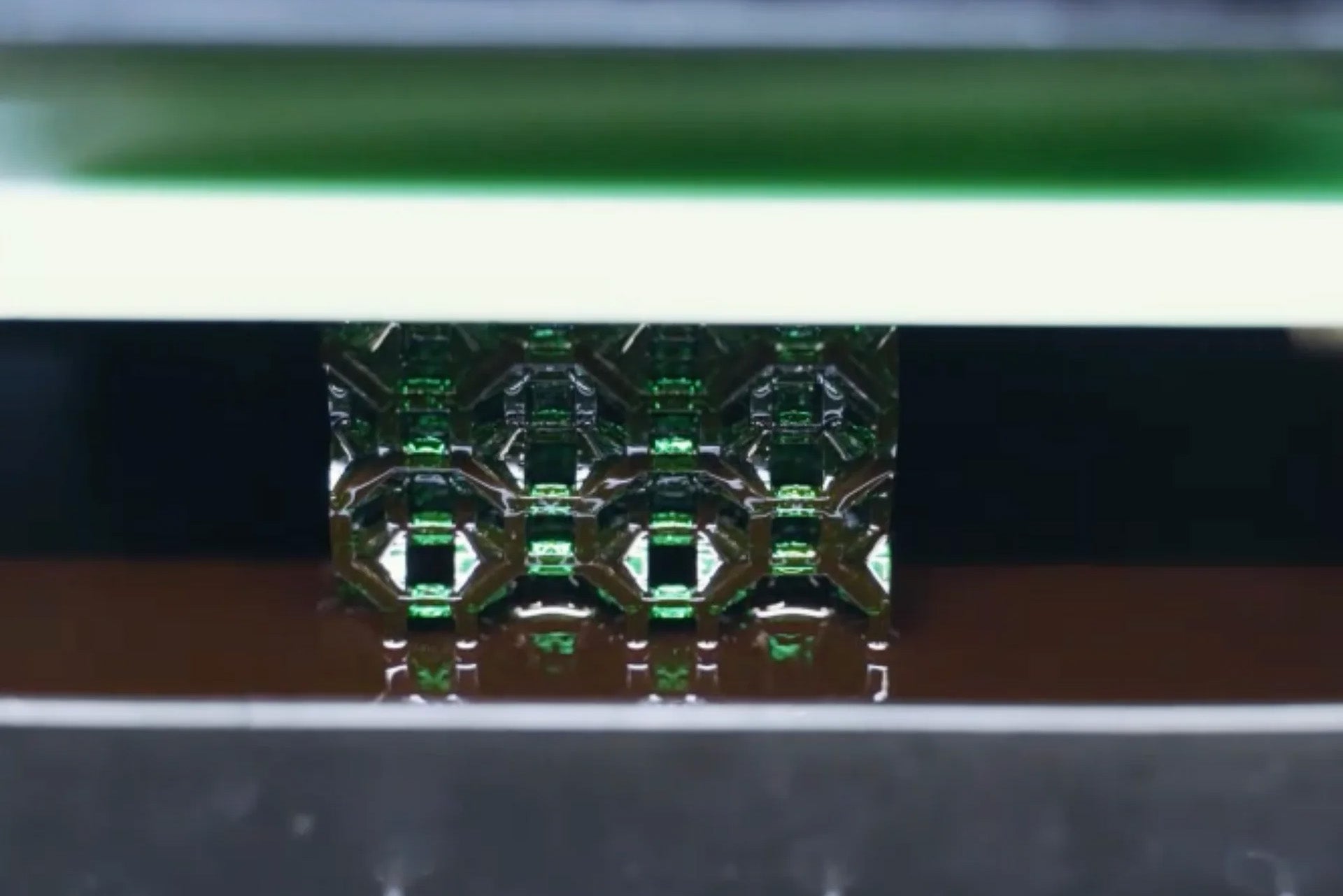

After the picker is lowered into the resin tank, an industrial UV projector projects a cross-section of the component to be built through the transparent tank floor onto the resin. The UV light image energizes the resin, causing it to harden where the light hits it.

#3

This creates a layer of the component. The build platform moves up slightly, creating a defined gap between the tank floor and the recently produced layer. In an iterative process, the UV projectors produce a component with the highest level of detail, layer by layer.

For your component

Our DLP materials

3DM impact

Specs3DM tough

SpecsBASF Ultracur3d ST 45 B

SpecsDetails MedicalPrint Clear

SpecsGraphy S-Plastic S100M

SpecsGraphy S-Plastic S100M Gray

SpecsHenkel Loctite 3172 Tough High Impact Gray

SpecsHenkel Loctite High Toughthness HDT60 3843 Black

SpecsHenkel Loctite Ind147 HDT230 High Heat Black

SpecsHenkel Loctite Ind406 HDT1000 High Elongation Black

SpecsPro3dure Printodent GR-10 Guide Clear Transparent

SpecsLumentic's phosphorescence green

Specsour overview

Miicraft 3D printer

support

Do you have questions or need support in choosing the right manufacturing process?

Then contact us - one of our employees will help you as soon as possible!